The project has been initiated by INEOS Inovyn with the support of Greenwin and Logistic in Wallonia. The Walloon funding has been granted through the mechanism of “clusters of competitiveness”.

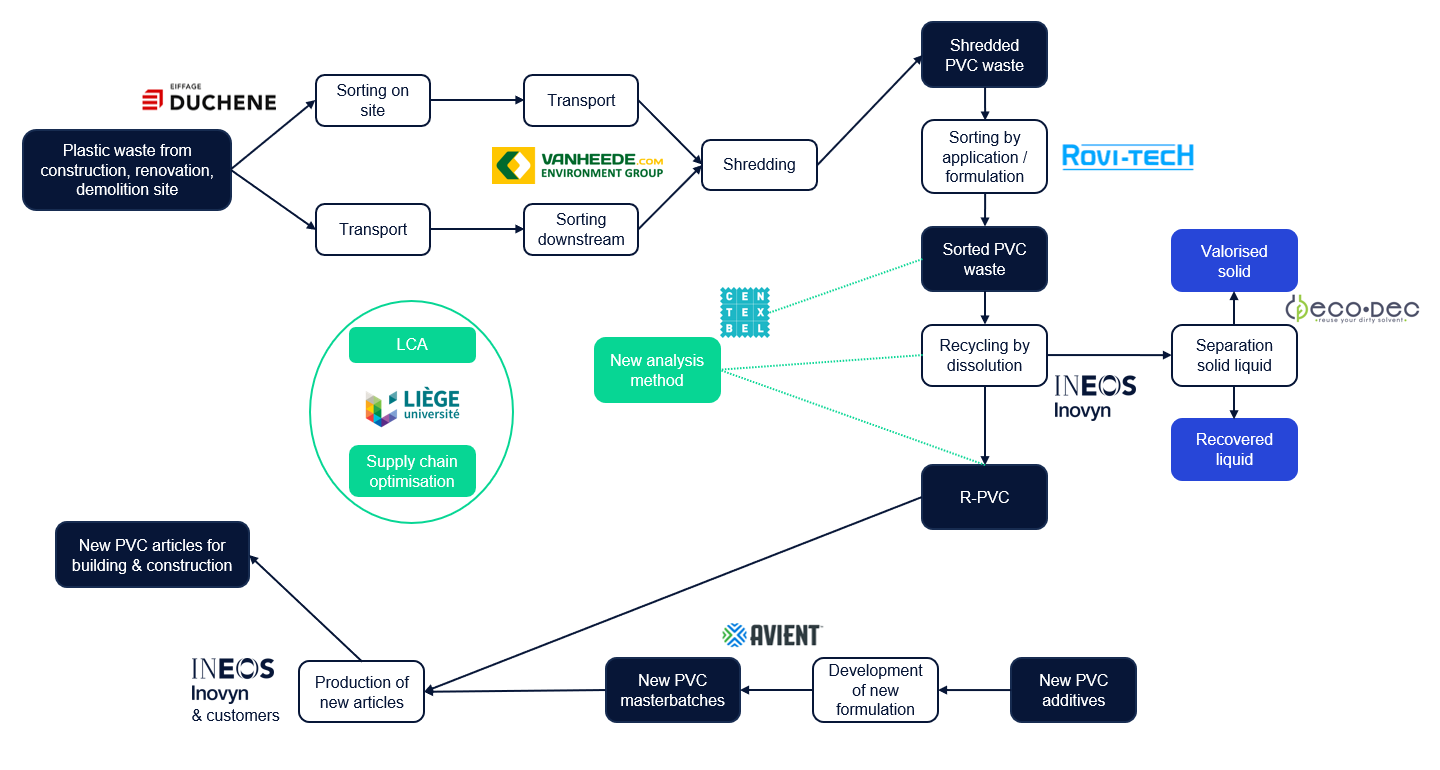

The CIRC-PVC consortium involves several industrial partners across the supply chain:

-

- Entreprises Générales Louis Duchêne: a building and construction company

- Vanheede Environmental Logistics: a waste collector and sorter

- ROVI-TECH: specialising in developing prototypes based on new sorting technology

- ECO-DEC: specialising in solid-liquid separation technology

- INEOS Inovyn: developing the dissolution and extraction technology

- Avient Corporation’s Belgium site: PVC master batch producer

These industrial partners are supported by Centexbel who will provide analysis capabilities and by the University of Liège, which will work on both the life cycle analysis and supply chain optimisation.

Running over 2 years the key goals of the CIRC-PVC project are:

-

- Improve the construction-demolition site management on selected sites, in order to collect selectively PVC and other plastics.

- Quantify what can be recovered (application, quantities) in function of the size of the site.

- Optimise container size for transport.

- Compare sorting on site or downstream.

- Develop specific automatic sorting technologies.

- Confirm, on basis of a pilot the dissolution-extraction technology.

- Propose to the market, high quality R-PVC for several applications.

- Prepare future industrial setup, optimising the logistic model for site location, waste collection radius and transport mode.

- Confirm on basis of a full LCA, the environmental gains versus the existing end of life solutions.